Embossing machine

abstract:HK018-220 embossing machine 1. Function: This machine is suitable for flat embossing of carpets. It has the characteristics of one-time molding, strong three-dimensional effect, and not easy to restore deformation. 2. Pay attention to techn

Order Hotline:13963223996

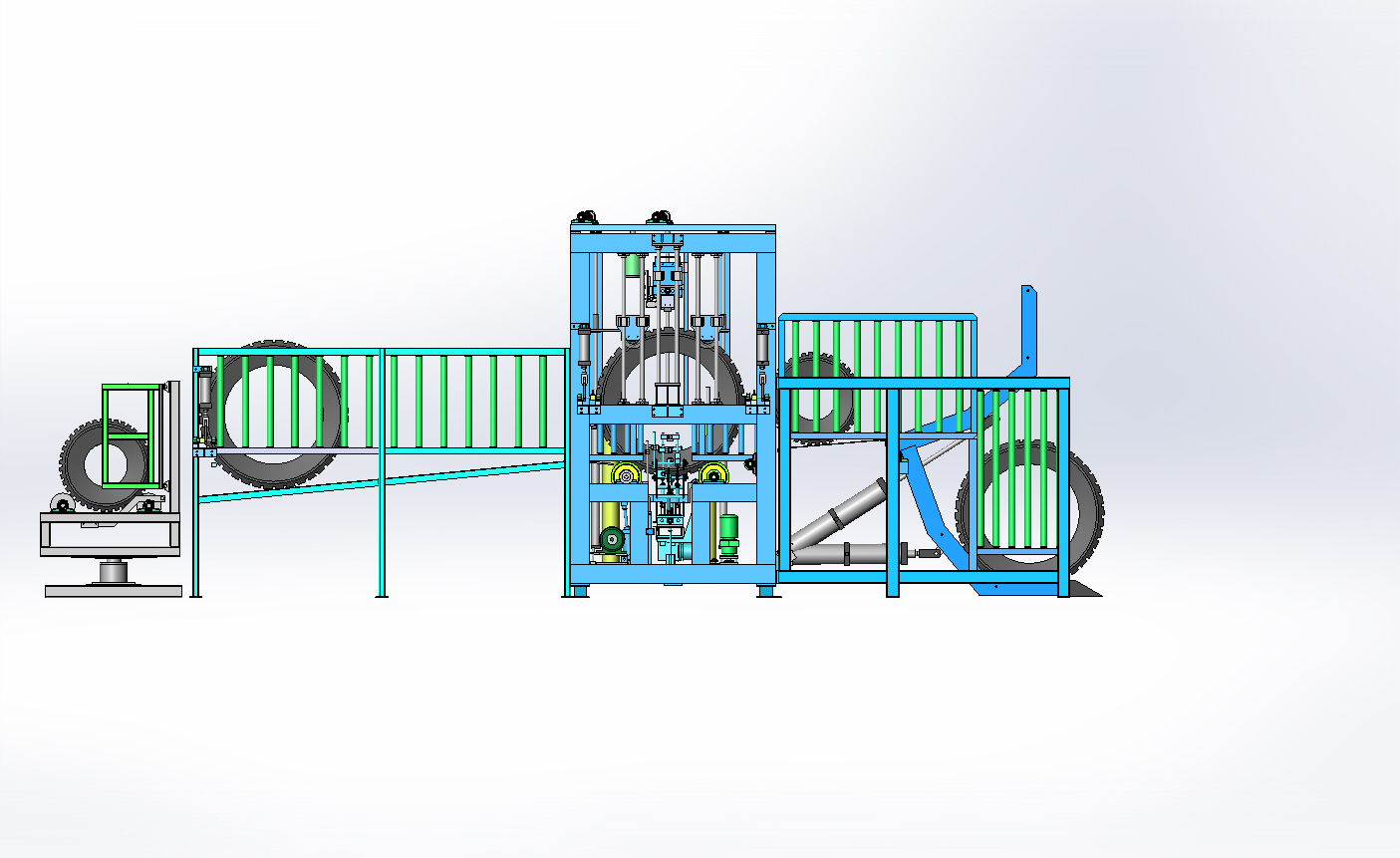

HK018-220 embossing machine

1. Function:

This machine is suitable for flat embossing of carpets. It has the characteristics of one-time molding, strong three-dimensional effect, and not easy to restore deformation.

2. Pay attention to technical parameters and instructions

1. Nominal width: 2200, 2400mm.

2. Working speed: 4 editions/minute

3. Form: manual type, automatic type.

4. Dimensions (length×width×height): manual type 2500×2700×900;

Automatic type 12300×2700×900mm

5. Embossing template: special cast aluminum, specification 1700×1900, can be customized according to user requirements.

6. Template: Embossing device, including a mold and a pressing mechanism. The mold has a space for placing the fabric. The mold is placed in the pressing mechanism. The pressing mechanism squeezes the mold to deform the fabric. The pressing mechanism has a heating structure for heating. The structure heats the mold to shape the fabric in the mold; the mold includes an upper template and a lower template. The upper template and the lower template are respectively provided with engraving surfaces with matching shapes. The engraving surfaces respectively squeeze both sides of the fabric to deform the fabric The fabric embossing device uses heating and pressure to deform the fabric in the mold, and uses cooling and pressure to shape the fabric, which is beneficial to save embossing time and improve the shaping effect.

7. Principle description: This machine includes a frame, a workbench, a pushing device and an embossing plate. The embossing plate is equipped with a three-dimensional pattern module with a concave-convex structure. The embossing plate is equipped with an electric heating device. The worktable includes two transmissions. The roller and the two driving rollers are connected by a conveyor belt, a fabric is placed on the worktable, and an automatic leveling device is arranged in the worktable at the lower end of the fabric. The automatic leveling device includes a connecting plate arranged on the frame and a flat plate connected by a spring on the connecting plate. An automatic leveling device is provided in the worktable at the lower end of the fabric, and the elastic force is automatically compensated by the compression spring in the leveling device, so that the pattern module on the embossing board can evenly contact the fabric during work, thereby achieving the embossed pattern The contour is clear and the color is uniform.

Contact Us

Shandong Huakai Electromechanical Technology Co., Ltd.

Shandong Huakai Electromechanical Technology Co., Ltd.