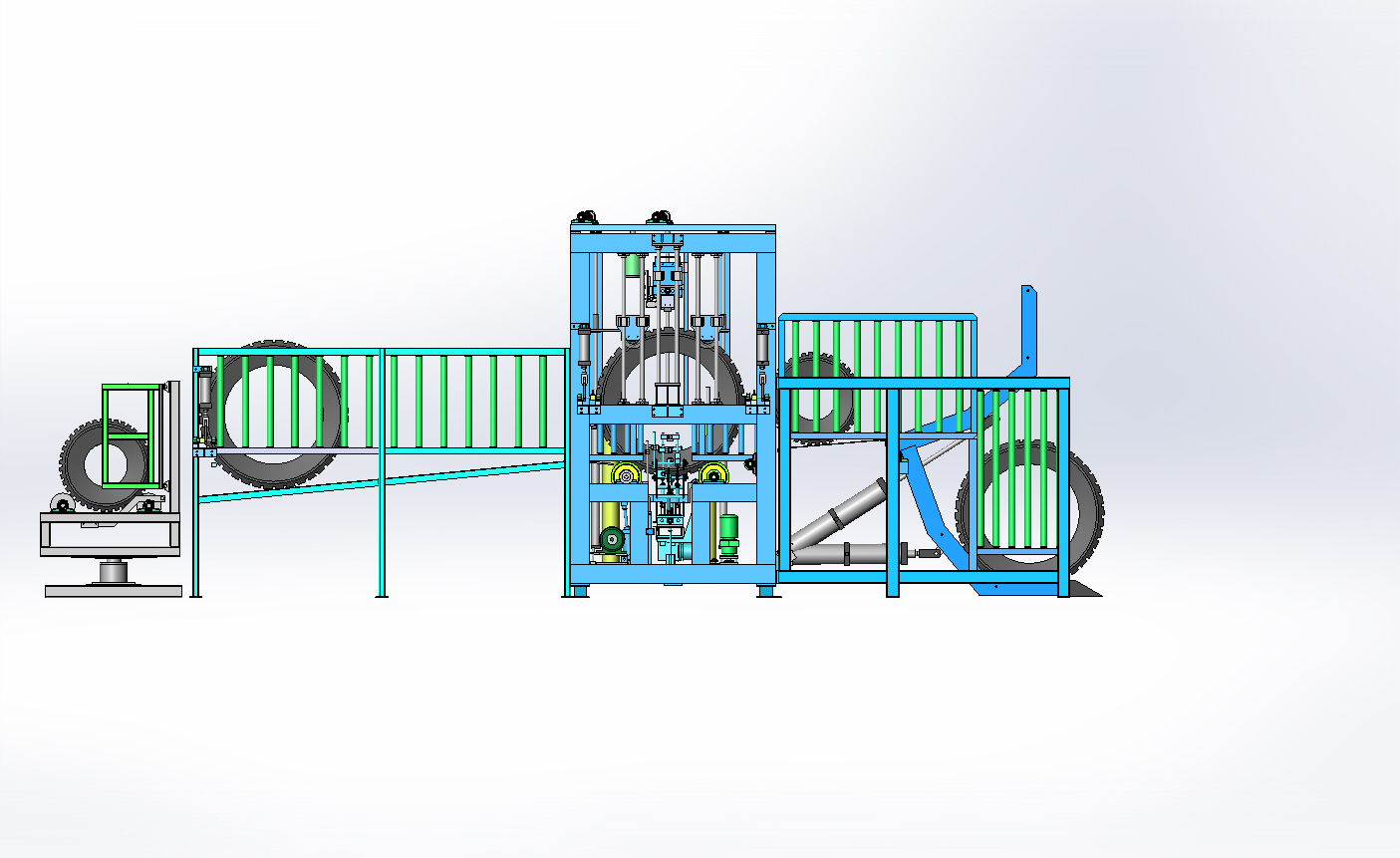

Tire automatic trimming machine

abstract:1. Purpose: Lanugo is an add-on to the tire production process and can cause many problems with tire quality. The tire hair of the tread will also cover the original tread pattern with reasonable design, which will cause problems such as wa

Order Hotline:13963223996

1. Purpose:

Lanugo is an add-on to the tire production process and can cause many problems with tire quality. The tire hair of the tread will also cover the original tread pattern with reasonable design, which will cause problems such as water drainage, friction, and braking performance. People pay more and more attention to the safety and reliability of automobile tire performance. This machine is suitable for repairing and scraping excess rubber hairs, rubber nails and flashes on the tread and sidewall of radial tires after vulcanization to remove the overflow. This machine is a device that cooperates with the output device of the vulcanizer and the automatic storage line to realize automatic trimming. It is composed of tire input, main engine and tire kick-out device. By detecting the size of the tire at the place where the tire is inserted, the position of the sidewall and tread trimming knife is automatically adjusted to trim the tire. After repair, it is generally below 2mm, which can meet the process requirements of each tire; finally, the tire is pushed out and entered into the subsequent automatic conveyor line.

2. Range of specifications: According to all-steel, semi-steel, low-pressure radial tires and tire inner diameter, outer diameter, width specifications, select HK7399: vertical, horizontal and other series of shaving machine models.

3. Main technical parameters and performance description:

1. Voltage: Phase-AC220/380V-50HZ Control voltage: 220VAC/24VDC

3. Control the air source pressure: 0.35 MPa

4. Air pressure of cylinder: 0.5 MPa

5. HK7399A all-steel radial tire inner diameter Φ48-Φ700mm; outer diameter Φ800-Φ1300mm; tire width: 200-450mm

6. HK7399B all-steel radial tire inner diameter Φ600-Φ800mm; outer diameter Φ1000-Φ1800mm; tire width: 300-600mm

7 Models can be designed according to customer requirements

Single tire time for 8 cycles: 30-50S

9. PLC programming is adopted to realize the automatic operation of the machine, and it can be equipped with QR code scanning to link with the large database of the enterprise.

10Vertical and horizontal structure optional.

4. Work flow design: The tire to be trimmed falls from the conveyor line and is received by the tire plate (shown by the dotted line in the figure below), and the direction of movement of the tire is indicated by the arrow in the figure. The tyre pushing cylinder receives the command and ejects the tyre to be trimmed, and the tire will fall on the trimming device in the direction of ejection. When the tire enters the trimming position, the tire rotates at a constant speed driven by the rollers, and the upper knife component starts to move downwards to trim the tread. At the same time, under the action of the feed mechanism, the side knife component starts to feed left and right and vertically to the two sides of the tire to be trimmed, and begins to trim the tire. Finally, the tyre kicking device receives the instruction to kick out the trimmed tire, and the tire enters the inspection process, so far the entire trimming work is completed.

Contact Us

Shandong Huakai Electromechanical Technology Co., Ltd.

Shandong Huakai Electromechanical Technology Co., Ltd.