Vacuum suction machine

abstract:Introduction of vacuum suction machine (patent number: ZL201420393838.7) 1. Function: Suitable for cotton, polyester cotton, linen and blended fabrics, blankets, carpets, towels, bath towels and other knitted fabrics or woven fabrics, vacuu

Order Hotline:13963223996

Introduction of vacuum suction machine (patent number: ZL201420393838.7)

1. Function:

Suitable for cotton, polyester cotton, linen and blended fabrics, blankets, carpets, towels, bath towels and other knitted fabrics or woven fabrics, vacuum absorption after washing. Using the principle of vacuum, the water in the fabric is fully sucked out to facilitate the next process, namely the one-time drying of the setting dryer, which can be continuously produced. It completely replaces the intermittent manual operation of the dehydrator, which improves the production efficiency. It also greatly reduces production costs for enterprises and saves manpower, material resources and financial resources. The process flow of this device in production and use:

Grey cloth→printing or pad dyeing→steaming→washing→vacuum suction machine→setting and drying→finishing.

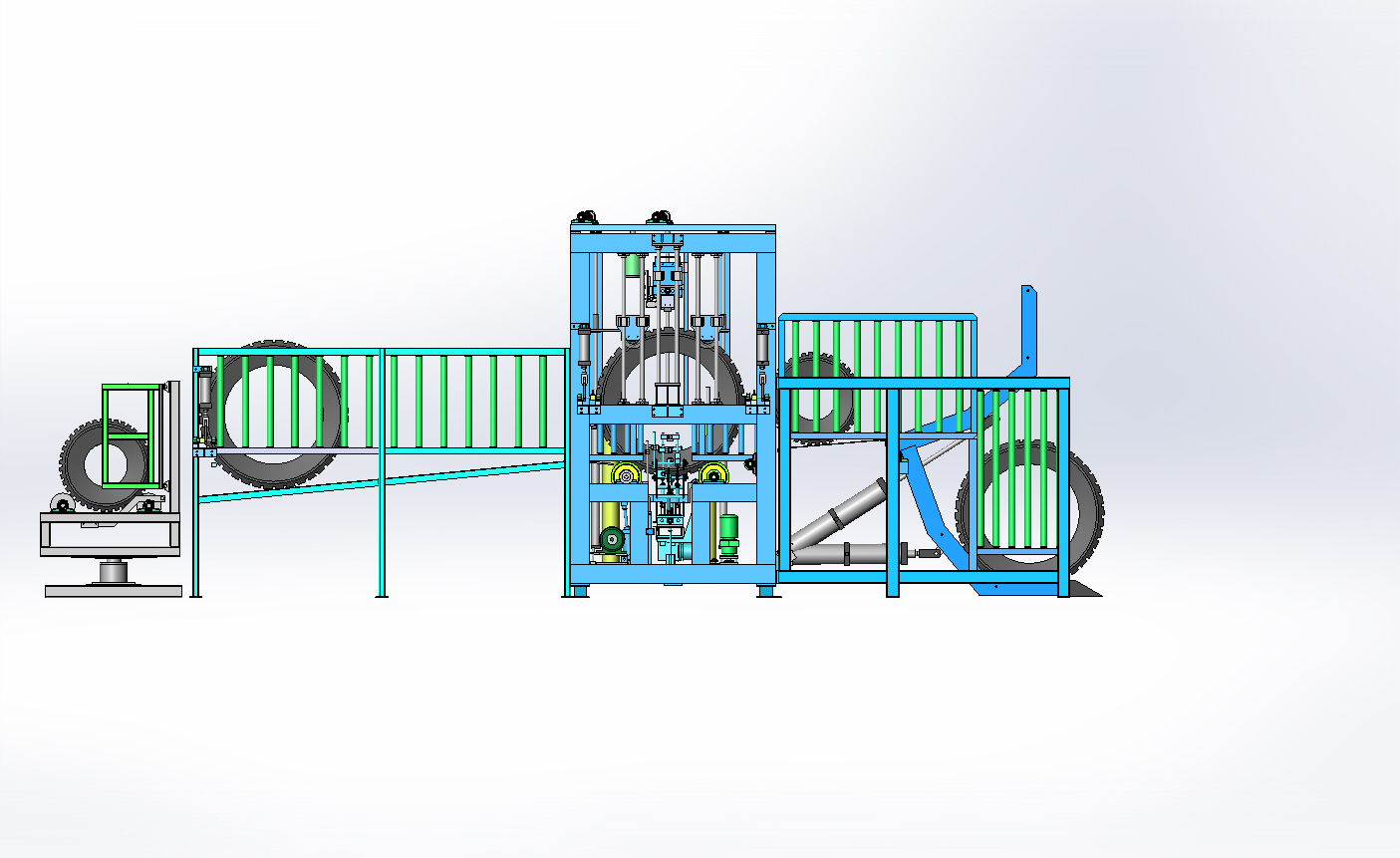

2. Structure introduction:

1. Including suction pipe, cyclone separator and Roots blower; the inlet end of the cyclone separator is connected with the suction pipe, the inlet pipe of the cyclone separator is also equipped with a filter air box, and the outlet end of the cyclone separator is connected with the roots blower pipe. The inlet of the Roots blower is equipped with an air inlet silencer, and the Roots blower is driven by a 37Kw three-phase electric motor. Roots blower, motor and air inlet silencer pipe are installed in the silencing hood. The outlet of the roots blower is also equipped with two sets of outlet silencer pipes. The lower end of the cyclone is connected to a pneumatic diaphragm pump for draining water. One side of the suction pipe is provided with densely distributed slit-type suction openings, and the slit-type suction openings are provided with a nylon plate anti-scratch material.

2. There is a liquid level controller inside the cyclone separator. When the water level reaches the upper limit, start the pneumatic diaphragm pump to discharge the water; when the water level reaches the lower limit, close the start diaphragm valve to maintain the pressure in the tank.

3. Roots blower is equipped with a 37kw-4 pole motor. The roots blower is connected to the motor through a belt. The roots blower motor is controlled by a frequency converter. The motor speed can be adjusted according to different fabric thicknesses. Effectively save electricity and energy consumption

4. Roots blower is the core part of the main work, and the speed is increased by the belt pulley, and the blower speed reaches 1650 rpm. Fully absorb the moisture in the fabric fibers. When the water and air are mixed into the cyclone separator, the water and air rotate on the inner wall by the cyclone separation principle to separate the water and discharge it through the diaphragm pump. The fluff and other impurities on the fabric are isolated when they pass through the filter cage and must be cleaned regularly every 6-7 days.

5. In order to eliminate noise, the machine is equipped with the soundproof cover of the Roots blower, which is welded with a 3# angle steel frame and covered with 70 thick high-density soundproof cotton. A φ600 silencer is installed at the inlet of the fan, and a silencer is installed at the outlet. The suction pipe is made of 150×150×3 mm thick stainless steel square pipe to ensure pressure resistance. The connecting pipeline is φ159×3 stainless steel seamless steel pipe. The separator is equipped with a liquid level controller. When the water level reaches the upper limit, the pneumatic diaphragm pump is started to discharge water; when the water level reaches the lower limit, the start diaphragm valve is closed to maintain the pressure in the tank.

6. The working process of the machine is:

Medium-thick fabric → attached to the suction pipe to run in open width → water and air enter the cyclone separator → water is separated and discharged through the diaphragm pump → air passes through the Roots blower → exhausted.

The key points of the machine innovation:

1. Using Roots blower, the advantage is high negative pressure, high flow and low power consumption. Instead of traditional vacuum pumps, they are large in size, noisy, and consume high power.

2. After the washed water-containing fabric passes through the machine, the residual rate reaches about 18-25%, which fully meets the needs of the dryer. The softener can be recycled and reused.

3. Open width operation, the whole machine works continuously, uninterrupted, and the production efficiency is improved. Replace the traditional batch centrifugal dehydrator.

4. The fabric fluff will not fall down, and the fiber will not be damaged or stretched.

5. The suction pipe adopts inclined slit and has a large suction mouth area. Use 15mm thick nylon board material to ensure that the fabric is not damaged

6. In order to prevent the fabric from deviating, cloth blocking tapes that follow the fabric are installed on both sides of the suction port to fully protect the negative pressure in the suction pipe from leaking.

7. In order to reduce the noise, the fan soundproof cover and inlet and outlet silencer pipes are installed.

Contact Us

Shandong Huakai Electromechanical Technology Co., Ltd.

Shandong Huakai Electromechanical Technology Co., Ltd.