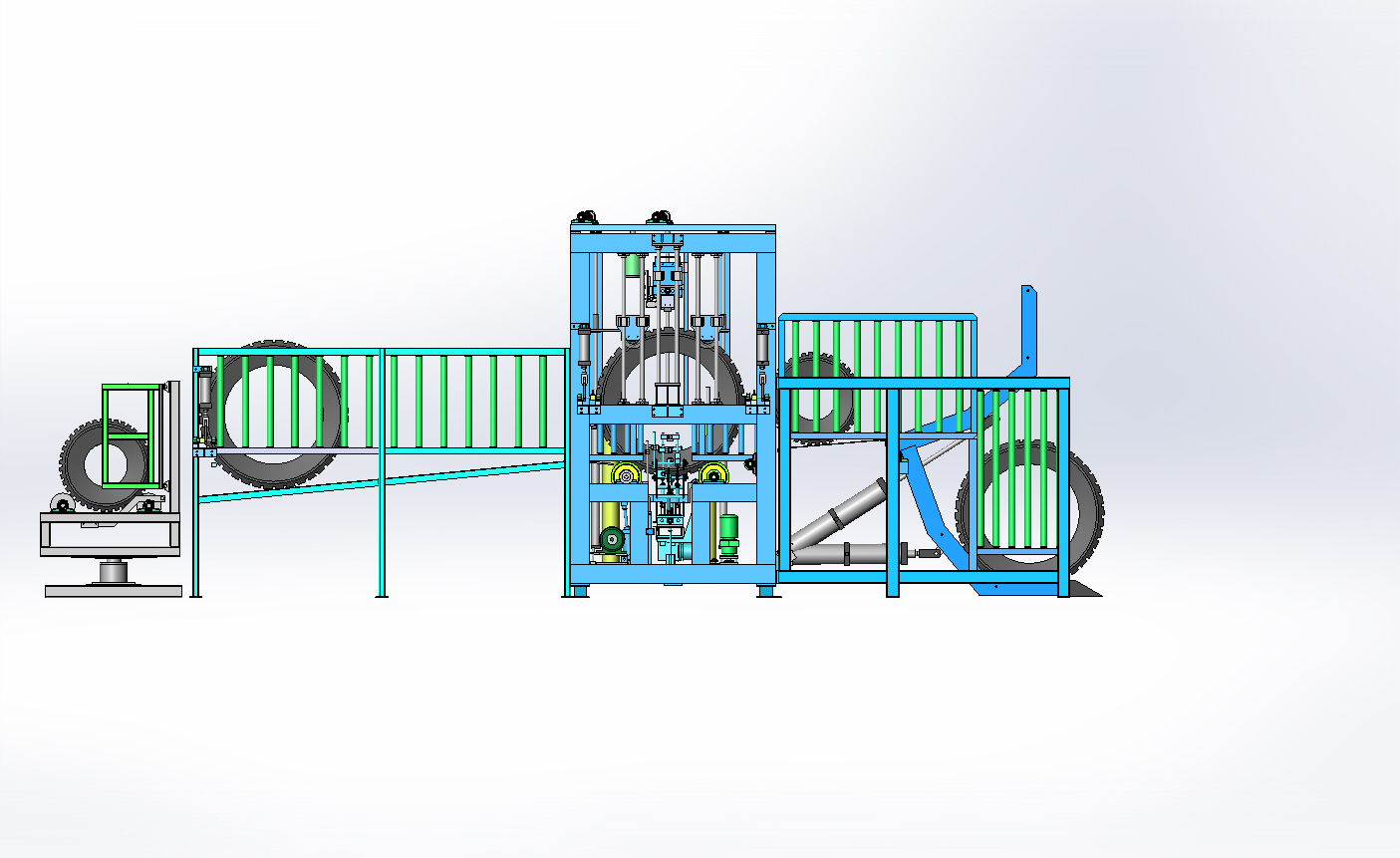

Straight roll mercerizing machine

abstract:Mercerizing machine series use This machine is suitable for the soda mercerizing process of cotton, polyester, linen and blended fabrics. It makes the fabrics luster, easy to color, meets the requirements of width, size and stability, and i

Order Hotline:13963223996

Mercerizing machine series

use

This machine is suitable for the soda mercerizing process of cotton, polyester, linen and blended fabrics. It makes the fabrics luster, easy to color, meets the requirements of width, size and stability, and improves the feel of the fabric.

2. Technical characteristics

1. Building block structure, according to product and process requirements, any combination of machine processes.

2. Mercerizing machine form: loose pile mercerizing machine (width 1800-2400mm)

Cloth clip mercerizing machine Straight roll cloth clip mercerizing machine (width 1800-2400mm)

Straight roll mercerizing machine (width 2600-3200mm)

3. AC variable frequency drive: machine speed: 10-80m/min

High-speed mercerizing locomotive speed: 15-100m/min

4. The cloth clip track is embedded with nylon plates, and the cloth clip chain is rolling friction, which is suitable for medium and high speed operation.

5. The center distance of the cloth clamp chain: 17.2m, 19.5m, 21.8mm, 24m, the number of alkali flushing is five flushes and five suctions.

6. The center distance of the cloth clamp chain: 14.9m, 17.2m, the number of alkali flushing is four flushes and four suctions.

Loose pile mercerizing machine

1. The equipment is an international initiative, and its comprehensive technical level has reached the international advanced level.

2. Six patented technologies realize the biggest breakthrough in mercerizing process equipment.

3. The concentration of lye is reduced from 240g/L-280g/L to 180g/L due to the principle of pine pile mercerizing process, which greatly saves the use of alkali.

4. The high liquid supply adopts the patented technology of submerged nip-through core liquid supply to realize high liquid carrying capacity of the fabric.

5. The patented technology of fixed-length vector control, after the fabric is rolled and loosened, the warp shrinkage is controllable and quantitative traction.

6. Compared with compact mercerizing, the annual saving of water, electricity, steam and alkali is about 2 million yuan, and the dye uptake rate is improved.

7. Wet cloth mercerizing effectively saves the energy consumption of retiring tickets, and achieves full absorption and penetration of mercerizing lye.

Contact Us

Shandong Huakai Electromechanical Technology Co., Ltd.

Shandong Huakai Electromechanical Technology Co., Ltd.