Color soaping machine

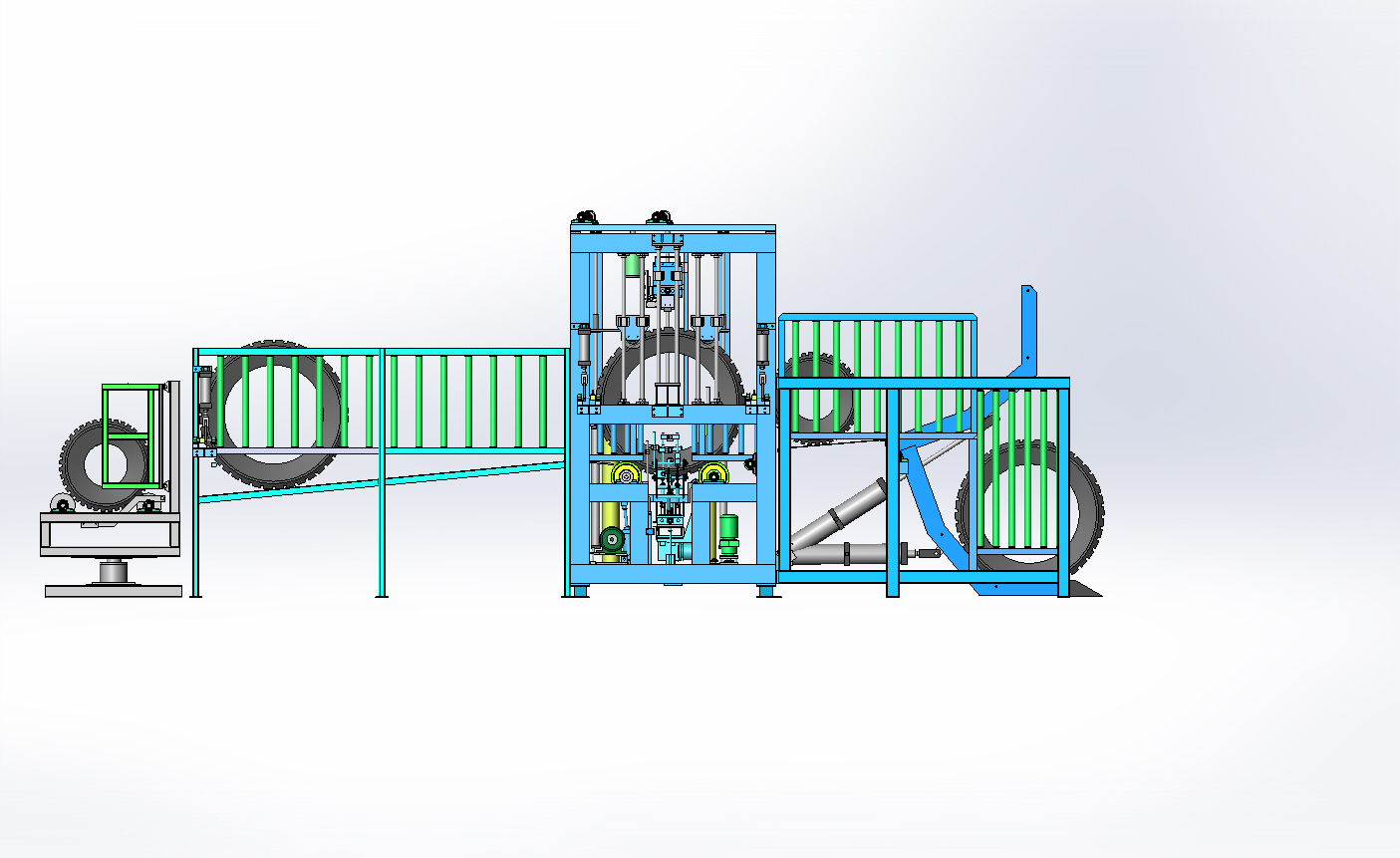

abstract:Color soaping machine 1. Purpose This machine is suitable for soaping cotton, polyester, linen and their blended fabrics after dyeing or printing to make the dyes color and remove dyeing impurities. 2. Technical characteristics 1. The build

Order Hotline:13963223996

Color soaping machine

1. Purpose

This machine is suitable for soaping cotton, polyester, linen and their blended fabrics after dyeing or printing to make the dyes color and remove dyeing impurities.

2. Technical characteristics

1. The building block structure can be combined arbitrarily according to different product processes.

2. Commonly used nominal width: 1800-3600mm.

3. Common roller diameter: φ150-φ200mm.

4. AC variable frequency drive, design speed: 10-80m/min.

5. Reduction steaming box: cloth capacity series: 50-80m.

6. Cloth capacity of the soaping steamer: 20-40m.

7. Efficient washing to ensure the color fastness after soaping.

Third, the performance of the reduction steam box

1. The box body is made of high-quality stainless steel plate, which is formed by laser cutting, CNC bending, and tailored welding on the large platform board.

Pill processing.

2. Synchronous drive adopts special multi-point dispersed common source asynchronous motor group variable frequency drive, which has strong wrinkle resistance.

3. The material slot is placed at the bottom of the box and can be automatically turned over for easy cleaning. Out of cloth water seal, the temperature inside the box is 102

℃+2℃, can be automatically controlled.

4. Flat-top structure, with stainless steel coils, use steam to heat the heat transfer oil to prevent dripping.

5. The two-story large glass window is convenient for operation and the upper part is quickly cooled.

6. Stainless steel bearing seat with mechanical seal, reliable performance.

7. Concave-convex structure at the bottom of the box, high strength, fast heating, and easy to clean.

8. The bottom of the box can be optional with a flat bottom and a structure that produces concentrated steam.

Contact Us

Shandong Huakai Electromechanical Technology Co., Ltd.

Shandong Huakai Electromechanical Technology Co., Ltd.