Temperature control system and liquid level control system

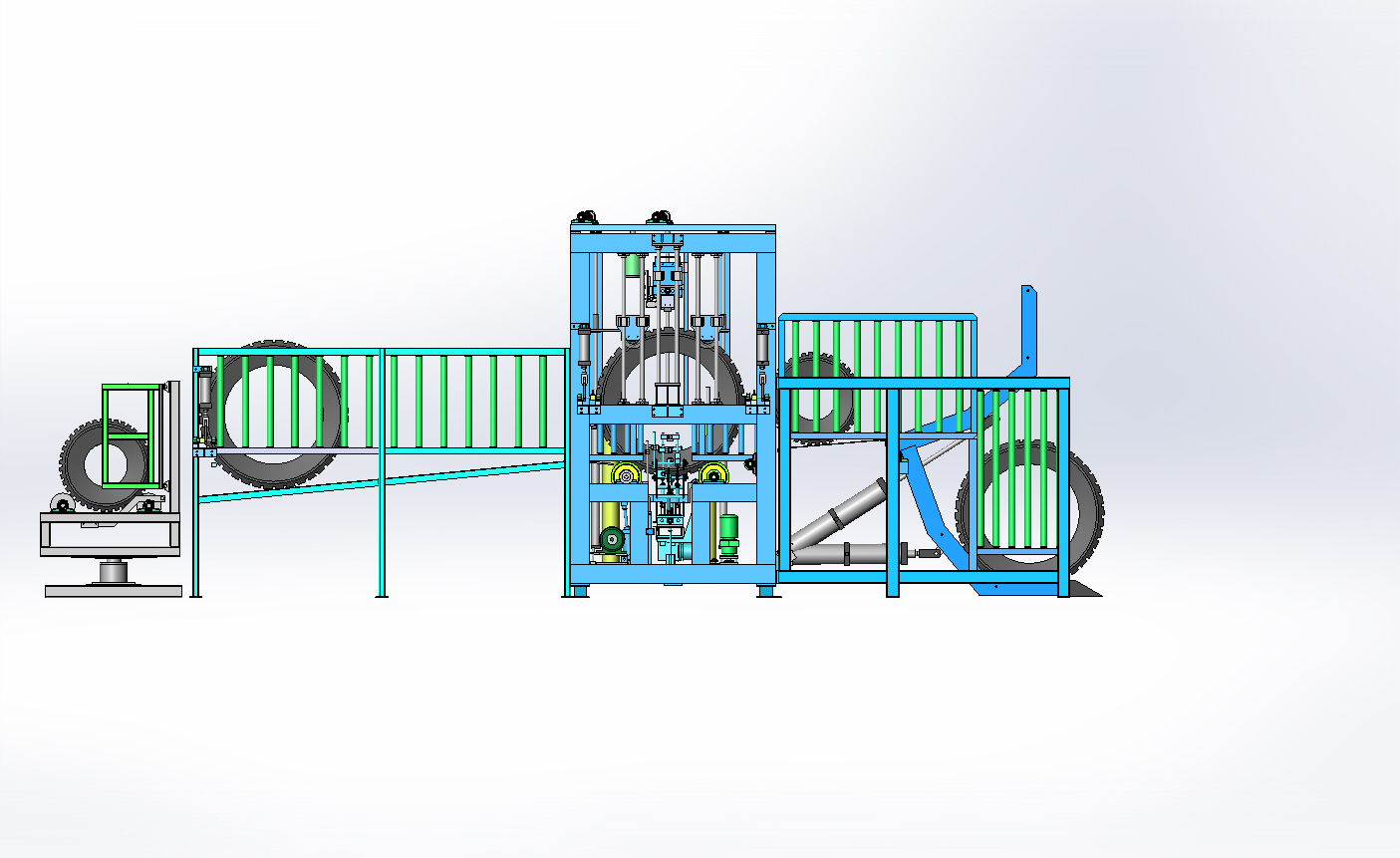

abstract:1. Product use It is suitable for the post-processing of inkjet printing of woven and tufted carpets, including unwinding, seaming, carpet finishing, pre-steaming, correction, printing, steaming, washing, drying, and winding. 2. Process flo

Order Hotline:13963223996

1. Product use

It is suitable for the post-processing of inkjet printing of woven and tufted carpets, including unwinding, seaming, carpet finishing, pre-steaming, correction, printing, steaming, washing, drying, and winding.

2. Process flow:

Unwinding and centering cloth feeding→platform→-joint-→cloth storage rack-→brushing-pre-steaming→-centering device→inkjet printing machine (provided by the user)→steam box→vacuum suction machine→three proofing Device →-Mesh belt dryer → Rear cloth storage rack → Traction small rolling cart →-Cloth inspection-→ Rolling device

3. Main technical description

1. Nominal width: 4000mm

2. Mechanical speed: 0-5m/min

3. Heat source: steam, natural gas or heat transfer oil

4. Electrical control: AC frequency conversion multi-unit control, synchronously linked with the printing machine for speed regulation.

Contact Us

Shandong Huakai Electromechanical Technology Co., Ltd.

Shandong Huakai Electromechanical Technology Co., Ltd.